Exploring the Duty of an Optical Fibre Diameter Analyser in Ensuring Product High Quality

The function of an optical fibre diameter analyser is pivotal in maintaining product quality within the telecommunications industry. These gadgets action fibre diameter with accuracy, ensuring consistency and performance. Variations in diameter can result in significant signal loss, affecting communication integrity. As makers go for excellence, understanding the mechanisms behind these analysers ends up being essential. What innovations lie in advance in this area, and just how will they shape the future of optical fibre production?

Understanding Optical Fibre Diameter Dimension

Gauging the diameter of optical fibres is a crucial process in guaranteeing the efficiency and dependability of fibre optic systems. Precise measurement is crucial, as variants in diameter can greatly influence signal transmission and total system efficiency. The measurement process typically utilizes sophisticated tools and methods, such as laser micrometers or optical fibre diameter analysers, which supply accurate, real-time data.These devices can analyze fibres' diameters with extreme precision, typically to micrometre degrees. This accuracy aids identify possible problems or variances in the production process. In addition, understanding the diameter measurement entails identifying the importance of elements such as temperature level, stress, and product residential properties, which can influence the final measurements. By maintaining rigid measurement protocols, manufacturers can assure that the optical fibres fulfill industry requirements and specifications, eventually adding to the long life and efficiency of fibre optic networks.

The Importance of Uniformity in Optical Fibre Manufacturing

Uniformity in optical fibre production is crucial for guaranteeing accuracy in producing processes. Variants in diameter can significantly impact efficiency metrics, influencing the general quality and reliability of the fibre. As a result, standardization and quality assurance measures are vital to preserve harmony and improve product performance.

Precision in Production Processes

Effect On Efficiency Metrics

Making certain uniformity in optical fibre diameter substantially affects performance metrics throughout various applications. Consistent diameter results in suitable light transmission, lowering signal loss and enhancing overall efficiency. When fibres maintain a common dimension, the likelihood of problems diminishes, improving reliability in telecoms and data transfer (optical fibre diameter analyser). Additionally, consistent sizes assist in easier integration into existing systems, decreasing compatibility concerns. Variations in diameter can cause changes in attenuation and diffusion, adversely influencing performance. By utilizing an optical fibre diameter analyser, suppliers can closely monitor and readjust production procedures, fostering a higher level of uniformity. This consistency not just boosts the top quality of the end product however also enhances customer contentment, showing important for preserving competitive advantage in the optical fibre market

Standardization and High Quality Control

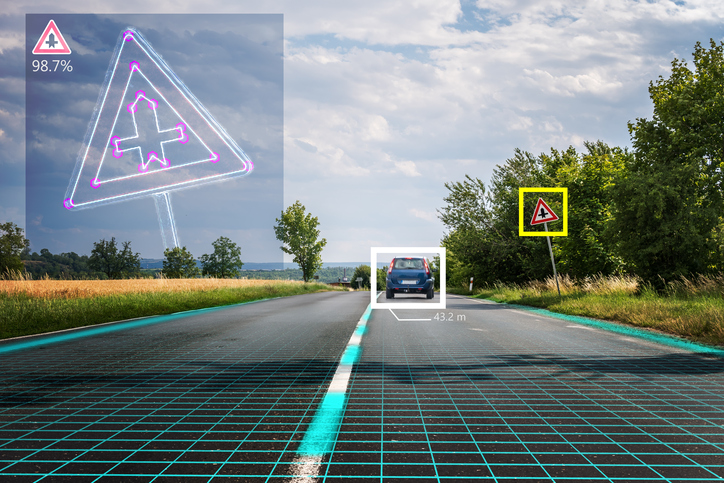

How Optical Fibre Diameter Analysers Work

Optical fibre diameter analysers operate through a combination of light transmission and advanced measurement techniques to precisely evaluate the diameter of optical fibres. These gadgets utilize a laser or LED light resource that emits a beam of light routed at the fibre under assessment. As light communicates with the fibre, it is refracted and scattered, enabling specific measurements.The analyser captures the light utilizing a high-resolution electronic camera or photodetector, which converts the optical signals into electric signals. Advanced formulas after that process these signals, calculating the diameter based on the strength and circulation of the light.The system usually consists of calibration features to assure accuracy, utilizing recognized requirements to validate measurements. By continually monitoring the fibre diameter, these analysers aid maintain conformity with market standards and specs, guaranteeing see page constant product top quality. Enhanced automation in modern analysers further simplifies the procedure, assisting in real-time analysis for suppliers.

Effect On Signal Integrity and Communication Reliability

A constant and accurate optical fibre diameter is crucial for maintaining signal integrity and communication integrity in fibre optic networks. Variations in diameter can lead to increased light loss, resulting in abject signal top quality and decreased transmission distances. When fibres are not uniform, concerns such as modal dispersion and attenuation may emerge, which can misshape the information being transferred and bring about errors in communication.Furthermore, irregularities in fibre diameter can impact the performance of ports and splicing, bring about more signal deterioration. This incongruity can compromise the total dependability of network systems, impacting everything from web speed to telecommunication clearness.

Enhancing Production Effectiveness With Advanced Technology

Keeping consistent fibre diameter is essential for guaranteeing trusted interaction systems. Advanced technology, particularly the optical fibre diameter analyser, plays an important function in improving making efficiency. By offering real-time dimensions and exact information concerning fibre sizes, this modern technology allows producers to promptly determine deviations from needed requirements. Manufacturing processes can be changed quickly, decreasing waste and minimizing downtime.The assimilation of automated systems enhances top quality control, allowing for constant visit this website monitoring throughout the production process. This not only accelerates production however additionally enhances total product high quality, resulting in fewer issues. Furthermore, advanced analytics allow suppliers to enhance their procedures based upon empirical data, assisting in continual renovation. Therefore, the optical fibre diameter analyser adds substantially to minimizing functional costs and boosting throughput, ultimately promoting a much more competitive side in the marketplace. By embracing these improvements, suppliers can ensure their items satisfy the highest possible requirements of quality and integrity.

Future Patterns in Optical Fibre Quality Control

As the optical fibre sector progresses, future patterns in quality control will prominently feature breakthroughs in measurement innovation. These technologies will certainly make it possible for a lot more precise assessments of fibre diameter, boosting overall item stability. Furthermore, the assimilation of automatic quality assurance systems promises to simplify procedures and enhance consistency in production.

Advancements in Measurement Technology

With the constant evolution of optical fibre technology, the demand for accurate measurement devices is much more important than ever. Recent developments in measurement technology have resulted in the growth of sophisticated optical fibre diameter analysers that make use of high-resolution imaging and laser-based methods. These technologies allow suppliers to accomplish greater precision and repeatability in diameter dimensions, vital for maintaining rigid top quality criteria. In addition, the assimilation of expert system and equipment understanding algorithms enhances information evaluation, permitting real-time modifications throughout production processes. As the sector welcomes these technical advancements, they assure to enhance performance, decrease waste, and guarantee the integrity of optical fibres in numerous applications, inevitably supporting the growing requirement for high-performance interactions framework.

Automated Quality Control Equipment

While the optical fibre market continues to development, the implementation of automated top quality control systems is positioned to revolutionize top quality assurance processes. These systems use innovative algorithms and real-time information analysis to keep an eye on fibre diameter and other critical criteria with unmatched accuracy. By incorporating optical fibre diameter analysers with automated systems, producers can identify discrepancies from specs immediately, reducing the danger of problems. Furthermore, automation lessens human mistake, boosts consistency, and increases manufacturing timelines. As sectors progressively take on Sector 4.0 concepts, the role of automated quality control systems will increase, promoting a seamless link in between production and quality control. This change not only assures greater item high quality but likewise cultivates development and effectiveness throughout visit this site right here the manufacturing process.

Frequently Asked Questions

What Aspects Impact the Optical Fibre Diameter Measurement Accuracy?

Variables influencing optical fibre diameter measurement precision consist of environmental conditions, calibration of measurement equipment, operator method, the level of sensitivity of the determining gadget, and the physical buildings of the fibre itself, such as product make-up and surface area irregularities. (optical fibre diameter analyser)

Just How Frequently Should Optical Fibre Diameter Analysers Be Adjusted?

Calibration regularity for optical fibre diameter analysers normally depends on use intensity and maker suggestions. Normal checks, usually month-to-month or quarterly, assurance measurement accuracy and dependability, therefore keeping the honesty of the production procedure.

Can Environmental Conditions Impact Dimension Outcomes?

Environmental problems can considerably influence measurement results. Variables such as temperature, humidity, and air pressure may affect the performance of measurement tools, possibly causing inaccuracies in the outcomes gotten from optical fibre diameter analysis.

What Are the Common Sorts Of Optical Fibre Diameter Analysers?

Exactly how Do I Pick the Right Analyser for My Manufacturing Requirements?

Picking the appropriate analyser includes assessing manufacturing demands, including fibre kind, diameter array, and measurement accuracy. In addition, analyzing the analyser's calibration, compatibility with existing equipment, and interface can substantially influence the decision-making process.